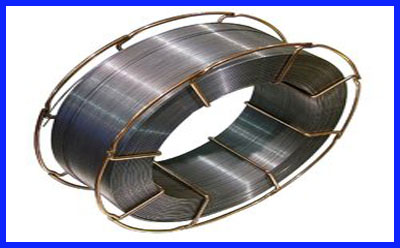

Stainless Steel Wires

Our range of stainless steel cold heading wires ensure high formability and cold extrusion properties. These wires are free from surface imperfections like seams, cracks, pitting and or scratch / die marks.

We are the leading supplier & manufacturer of stainless steel wires in sizes ranging from 0.10mm to 7.00mm in AISI 200,300 and 400 series. These wires are available in various finishes viz. soft, quarter (1/4) hard, half (1/2) hard or full hard in different surface finishes like bright, mat / dull depending upon the requirement of the buyers.

Our range of stainless steel cold heading wires ensure high formability and cold extrusion properties. These wires are free from surface imperfections like seams, cracks, pitting and or scratch / die marks.

Our stainless steel wires for steel springs are high tensile strength wires for precisions springs, compression springs, tension springs, wire form, pins and wire ropes. Wires can be supplied as per Customers specifications in ½ Hard, ¾ Hard or Full Hard condition.

Our stainless steel welding wires are suitable for stainless steel welding and cryogenic applications.